Blog

Manufacturing of Wines

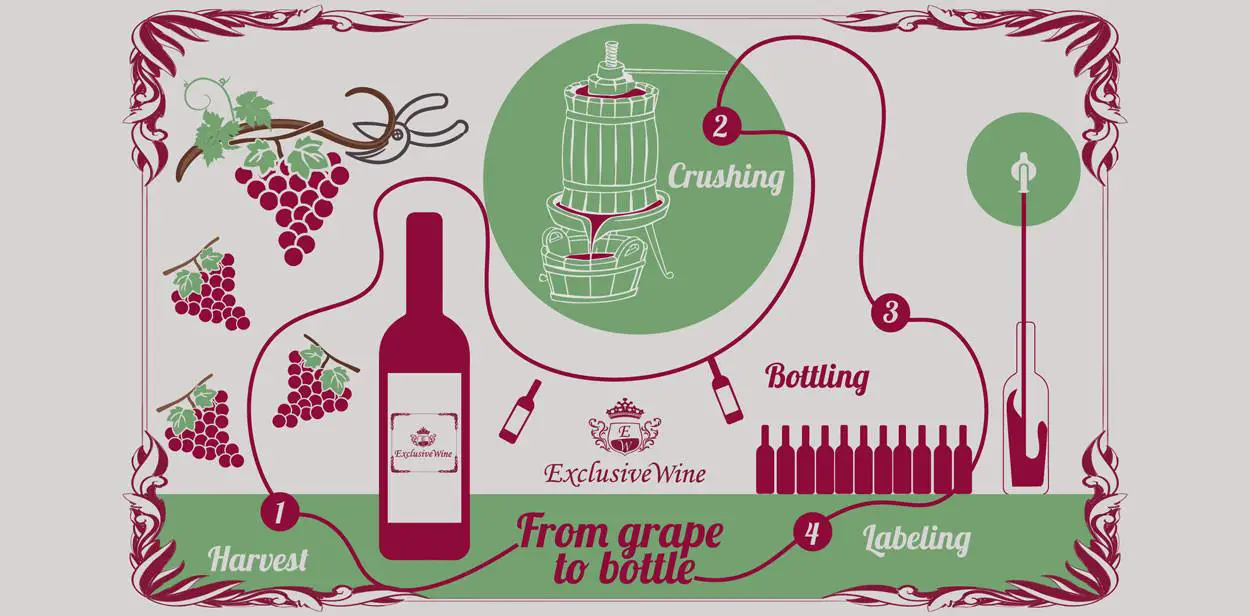

Manufacturing Process of Wines

Fermentation

- Grapes crushed → must + yeast

- Fermentation begins → alcohol + carbon dioxide

- 10% to 12% alcohol is standard – in case of most wines, sugar finishes before yeast.

- Left to nature, almost all wines would be dry – except the rare naturally sweet wines.

- Often, during fermentation, a thick residue forms on the top and acts as a cap. This is broke up regularly for continued (but controlled) air-contact.

- The casks are sealed but lose some wine through evaporation. The resultant empty space is called ullage. This is filled up with more wine as too much air will render the wine acetic acid.

- In many cases, fermentation is forcibly stopped by adding spirits, adding sulphur or micro-filtration.

Care of the Wine

Now a strictly controlled process in most countries – not an easy task for the maître de chais.

Racking – the wine is repeatedly racked. Its allowed to settle and drawn into fresh casks. The lees (residue) get separated.

Fining – even after racking the wine is not completely clear. The fine particles are removed by using fining agents like isinglass, egg-white, etc.

Ageing – the wine is matured further to bring it to its prime. Different wines need different ageing periods – from 6 months to 5 years to 10 years and more.

Bottling – most wines improve in the bottle – shorter for whites and longer for reds.

Corking – results in continued air-contact – minute, but does make a difference.

Corks are made with the bark of the oak tree. Deforestation controls has resulted in the introduction of fireboard/plastic corks, even screw caps.

WINE FAULTS

Wine is a living thing, and its life essentially consists of a gradual process of oxidation, eventually leading to its “death.” Not unlike what happens to people, really… And, just like a person, a wine may develop an ailment that can alter or shorten its growth and evolution.

Such ailments can be caused by a variety of factors, although modern viticultural and winemaking techniques make it increasingly rare to come across a wine in a bad state.

At times, the perception of a wine’s quality may also be somewhat subjective: what some consider a flaw, others see as a virtue. (Too much fruit or oak, etc.)

We will focus on olfactory defects or “off-aromas,” taking a closer look at the five most common faults:

1. A corked smell

The root cause of cork taint is often found in the source of the raw material: a cork oak that got infected by mold. The problem may also originate in the winery, in its wooden structural elements or oak barrels.

Cork taint is caused by TCA (Trichloroanisole), a natural compound that forms when organic elements (phenols) found in grapes, cork, barrels, etc. break down and combine with chlorine. Why? A lot of wine producers want very white corks and use chlorine to bleach the cork tree bark. The problem arises when small pockets of moisture develop, offering fertile terrain for fungi to nest, grow and compromise the cork.

2. A smell of sulfur

Nowadays, sulfur dioxide (SO2) is used as an anti-oxidant and antiseptic. An excessive amount, however, gives wine the unmistakable smell of a burnt match head. White wines contain the highest levels of SO2, because they are “naked,” meaning they do not contain protective polyphenols or tannins. In order to prevent premature oxidation, a greater amount of sulfur is added to these wines.

When tasting the wine, it produces an itchy or burning sensation in the nose and an acrid, earthy taste in the mouth.

3. The smell of rotten eggs

This is the result of a chemical compound called hydrogen sulfide (H2S). The smell usually appears while decanting an insufficiently oxygenated wine in warm climates. In other words, it is a reduction problem.

Hydrogen sulfide can come from two sources:

· The grape—from the fungicides used in treating the vine.

· Or from adding excessive amounts of sulfur dioxide (SO2) to the must or finished wine.

Another well-known fault associated with hydrogen sulfide is something called bottle shock. This is due to the presence of mercaptans and sulfur dioxide(SO2) produced by mold on the corks used in sealing the bottles. The result is an unpleasant smell reminiscent of wet dog.

4. Smells like vinegar

Volatile acidity. This happens when wines have been exposed to oxygen for a long time, either because they were not sealed properly or because they were stored upright for a prolonged period. In the latter case, the cork dries out and shrinks, resulting in a process of macro-oxygenation. The chemical compound responsible for this is ethyl acetate.

5. Smells humid/musty

This stems from damp cellars or closed spaces lacking proper ventilation or cleanliness where old tanks and containers have not been adequately sterilized (poorly maintained storage facilities, garages, etc.) Filamentous fungi are responsible for this particular fault.

The wine may look normal, but gives off a moldy smell and a very pronounced humid or musty taste.

You can Also Check this video below to learn :- How red wines and white wines are made